- The operation of the textile industry from January to August 2024!

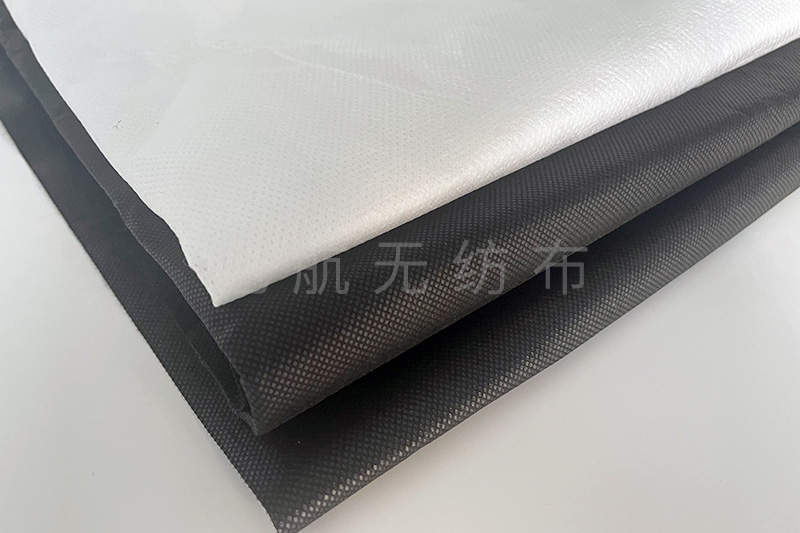

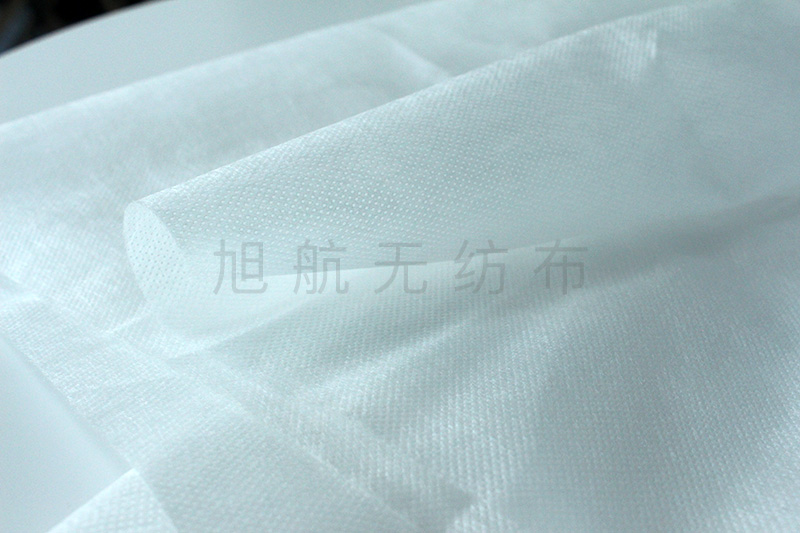

- Application of automotive interior non-woven fabric

- Automotive interior non-woven advantages of non-woven fabric

- The global economic recovery has held up better than expected

- From January to August this year, the total profit of China's textile industry was 100.62 billion yuan, an increase of 14.4%!

- If there is a need for automotive interior non-woven fabrics, please contact us!

- Contact: Mr Li

- Tel: 0086-139 2680 4227

- Fax: 0086-0769-85080625

- Email: xh@xhnonwovens.com

- Add: No. 15, Baihao Industrial Street, Houjie Town, Dongguan City, Guangdong Province

Since the 1970s, various charging technologies and charging technologies by mixing different fibers have been developed and utilized. The direct result is the current electrostatic electret method (process). The current electret methods of meltblown cloth electrostatic generator mainly include electrostatic spinning method, corona charging method, friction electrification method, thermal polarization method, low-energy electron beam bombardment method and so on. The current electret methods mainly include electrospinning, corona charging, friction electrification, thermal polarization, and low-energy electron beam bombardment. At present, meltblown non-woven fabrics are widely used in the field of filter materials.

Meltblown cloths are all polypropylene. Polypropylene is a homopolymeric polymer material. Because polypropylene has a particularly poor conductivity, it becomes a good electret material. , How does the meltblown fabric electrostatic generator apply static electricity to the meltblown nonwoven fabric?

Principle of action

The electrostatic generator is composed of an electrostatic transmitter and a high-voltage power supply. The high-voltage power supply provides the negative (or positive) high voltage of the electrostatic transmitter, so that the electrostatic transmitter emits negative pressure static electricity (or positive pressure static electricity), and then the object or workpiece is charged for process operation. The higher the voltage, the larger the effective range.

In fact, it is a high-voltage discharge. The charge is attached to the meltblown non-woven fabric. The electret treatment makes the filter material fibers charge. Combined with the dense characteristics of the meltblown ultrafine fiber material, a large number of electrodes are formed between the charged fibers. The charged fibers are not only Like a magnet, it can attract most of the charged particles in the environment, and it can also polarize the uncharged particles, and then adsorb some smaller pollutants. Even viruses, such as nano-sized substances, can also be electrostatically adsorbed or Charges repel and block.

The meltblowing die head includes a die head body, a spinneret and an air plate. The spinneret and the air plate are detachably installed in the die body. A spinneret hole is provided in the spinneret, and there are a number of nozzles between the nozzle plate and the air plate. There are several gas circulation channels in the main body of the die head. The gas circulation channels communicate with the gap grooves. The outer wall of the main body of the die head is provided with a gas pipe connection end. The gas pipe connection end is connected to the gas through the gas pipe. The cavities are connected, one end surface of the spinneret hole of the spinneret is fixedly connected with a spacer, and the other end surface of the spinneret hole is fixedly connected with a pipe connection device. The nozzle hole is connected to the outlet of the screw extruder through the pipe connection device. The feed port is connected.

In summary, such a melt blown cloth electrostatic generator can be widely used in industrial production (filming, painting, flocking, sorting, melt blown cloth) and scientific research and other fields for various high-voltage electrical equipment, electrical components, insulating materials Conduct an electrostatic discharge test under DC high voltage to make one material charged and adsorb to the surface of another material for the purpose of positioning, fixing, and adsorbing the meltblown cloth.

- Application of automotive interior non-woven fabric

- The operation of the textile industry from January to August 2024!

- Automotive interior non-woven advantages of non-woven fabric

- The global economic recovery has held up better than expected

- From January to August this year, the total profit of China's textile industry was 100.62

- If there is a need for automotive interior non-woven fabrics, please contact us!

- The use area of automotive non-woven fabrics

- Textile industry scale and current situation analysis!

- Xu Hang new materials wish our motherland prosperity, prosperity and peace!

- In the first half of 2024, the economic operation of China's textile industry is basically